首页 > 新闻资讯

首页 > 新闻资讯

Cutting tool structure

2018-05-09 18:41:37

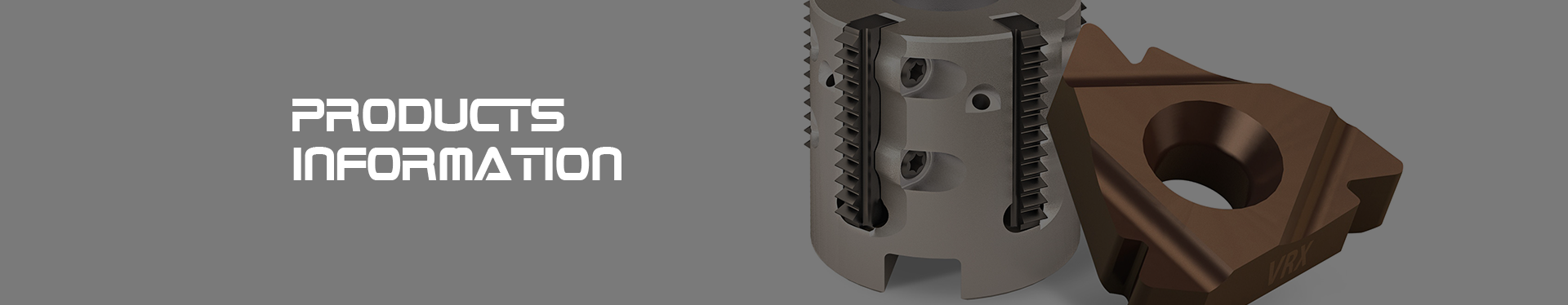

The structure of various knives is made up of clamping part and working part. The clamping part and working part of the overall structure are all on the cutter body, and the working part of the inserted tooth structure cutter (knife tooth or blade) is mounted on the cutter body.

The clamping parts of the cutting tool include two types of belt and handle. With the inner hole set on the spindle of the machine tool or the axis of the heart, the torsion moment is transmitted by the axial key or the end bond, such as the cylindrical milling cutter and the sleeve type milling cutter.

The tool with handle usually has three kinds: rectangular handle, cylindrical handle and conical handle. The cutter and the planer are generally rectangular handle, and the taper handle is subjected to the axial thrust by the taper, and the torque is transferred with the aid of friction. The cylindrical handle is generally applicable to the smaller twist drill and the vertical milling cutter, and the torque is passed through the friction force produced by the clamping. The shank of many shank tools is made of low alloy steel, while the working part is welded by two parts of high speed steel.

The working part of the tool is the part of the production and processing of the chip, including the blade, the broken or winding structure of the chip, the space of the chip or the storage of the chip, the channel of the cutting fluid and so on. The working part of some tools is the cutting part, such as the cutting tool, the planer, the boring knife and the milling cutter, and some of the working parts of the tool include the cutting part and the calibration part, such as the drill, the reamer, the reamer, the inner surface broach and the taps. The function of the cutting part is to remove chips by cutting edges, and the calibration part is to polish the machined surfaces and guide the cutting tools.

The working parts of cutting tools are of three types: integral type, welding type and mechanical clamping type.

The integral structure is to make the cutting edge on the knife body.

The welded structure is brazed to the cutter body of the steel.

There are two kinds of mechanical clamping structure. One is to clamp the blade on the cutter body, and the other is to clamp the brazed knife head on the cutter body.

Cemented carbide tools are usually made of welded structure or mechanical clamping structure, and porcelain cutting tools adopt mechanical clamping structure.

The geometric parameters of the cutting part have great influence on the cutting efficiency and the machining quality. Increasing the rake angle can reduce the plastic deformation of the rake face when extruding the cutting layer, reduce the friction resistance of the chip flowing through the front, thereby reducing the cutting force and cutting heat. But increasing the rake angle will also reduce the strength of the cutting edge and reduce the heat dissipation volume of the cutter head.

In selecting the angle of the tool, the influence of a variety of factors, such as the workpiece material, the tool material, the machining properties (coarse and fine machining), must be selected according to the specific conditions. Generally speaking, the angle of the tool refers to the different angles and angles of the actual working angle and marking, but the difference is usually very small when the angle of the annotation used in manufacturing and measuring is in the actual work, because the position of the tool is different and the direction of the cutting motion is changed.

The clamping parts of the cutting tool include two types of belt and handle. With the inner hole set on the spindle of the machine tool or the axis of the heart, the torsion moment is transmitted by the axial key or the end bond, such as the cylindrical milling cutter and the sleeve type milling cutter.

The tool with handle usually has three kinds: rectangular handle, cylindrical handle and conical handle. The cutter and the planer are generally rectangular handle, and the taper handle is subjected to the axial thrust by the taper, and the torque is transferred with the aid of friction. The cylindrical handle is generally applicable to the smaller twist drill and the vertical milling cutter, and the torque is passed through the friction force produced by the clamping. The shank of many shank tools is made of low alloy steel, while the working part is welded by two parts of high speed steel.

The working part of the tool is the part of the production and processing of the chip, including the blade, the broken or winding structure of the chip, the space of the chip or the storage of the chip, the channel of the cutting fluid and so on. The working part of some tools is the cutting part, such as the cutting tool, the planer, the boring knife and the milling cutter, and some of the working parts of the tool include the cutting part and the calibration part, such as the drill, the reamer, the reamer, the inner surface broach and the taps. The function of the cutting part is to remove chips by cutting edges, and the calibration part is to polish the machined surfaces and guide the cutting tools.

The working parts of cutting tools are of three types: integral type, welding type and mechanical clamping type.

The integral structure is to make the cutting edge on the knife body.

The welded structure is brazed to the cutter body of the steel.

There are two kinds of mechanical clamping structure. One is to clamp the blade on the cutter body, and the other is to clamp the brazed knife head on the cutter body.

Cemented carbide tools are usually made of welded structure or mechanical clamping structure, and porcelain cutting tools adopt mechanical clamping structure.

The geometric parameters of the cutting part have great influence on the cutting efficiency and the machining quality. Increasing the rake angle can reduce the plastic deformation of the rake face when extruding the cutting layer, reduce the friction resistance of the chip flowing through the front, thereby reducing the cutting force and cutting heat. But increasing the rake angle will also reduce the strength of the cutting edge and reduce the heat dissipation volume of the cutter head.

In selecting the angle of the tool, the influence of a variety of factors, such as the workpiece material, the tool material, the machining properties (coarse and fine machining), must be selected according to the specific conditions. Generally speaking, the angle of the tool refers to the different angles and angles of the actual working angle and marking, but the difference is usually very small when the angle of the annotation used in manufacturing and measuring is in the actual work, because the position of the tool is different and the direction of the cutting motion is changed.

Beautter Furniture Manufacture Co. Ltd Copyright Website:HeYou